HEAT TREATMENT LAB Prepared by. Turn off oven leaving the sample inside until cool.

Heat Treatment Lab Report Madalynngwf

Quenched and tempered i.

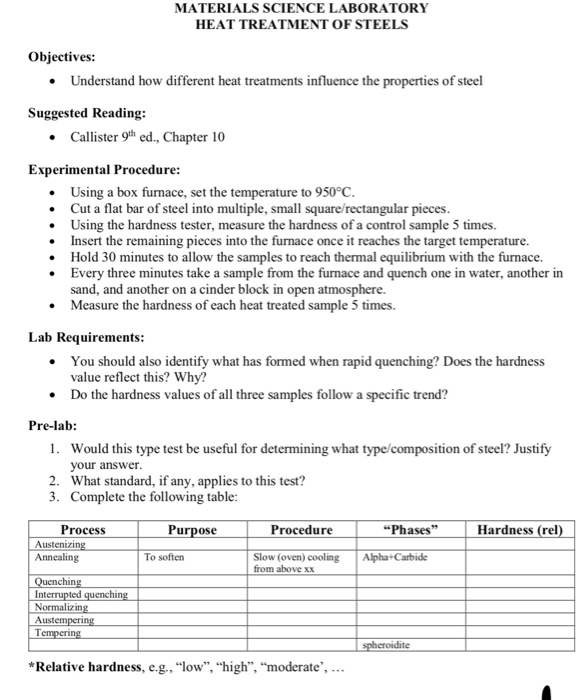

. Normalizing - Rapidly remove one specimen and allow it to cool in air on a ceramic base. The purpose of heat treating is to make a metal more useful by changing or restoring its mechanical properties. The purpose of this lab was to determine how different types of heat treating would affect a metal.

The specimen kept in the furnace allowed heat between 35 min to 1 hr. The specimen is taken out and any of the following steps are adopted as required the specimen is cooled against the air blower or fan. The heat-treating process is a method to alter physical and mechanical properties of the material.

Quench Hardening Rapidly remove two specimens and quench them in. Austenite is transformed from Pearlite. Through heat treating we can make ametal harder stronger and moreresistantto impact.

When steel is subjecting to 723C austenite will be formed. Keep the specimen inside the furnace and close the door. Alloying and heat treatments that advance the formation of small hard precipitates which interfere with the motion of dislocations attain the optimum strengthening of aluminum.

Conclusion In conclusion we find that the heat treatment of low and carbon steel specimenshave the greatest change in hardness and subsequent mechanical properties when heat treatment temperatures are 960C or greater. Switch on the furnace set the temperature control knob to given temperature. The paper Heat Treatment of Steel is a persuading example of a lab report on physics.

Use insulating gloves to open or close the doors to the furnaces. A total of 1 hour heating time should be adequate allowing roughly 45-50 minutes of soaking. MSE Department Lab Report Formatpdf.

The various steel samples were water quenched oil quenched and air cooled along with certain steels being tempered and requenched. Report Submitted by Emily Carvalho Leader Experiment No. To compare the hardness and microstructure of a 4340 to a eutectoid steel sample was cooled slowly versus a quenched sample.

Heating and cooling of metals during heat treatment is done in a controlled process. Physical and mechanical properties of metals can be altered without necessarily changing their shape. Either cool the specimens immediately after removal from the furnace or place in a designated area for slow cooling.

Experimental Procedure and Analysis Each lab will receive four samples to test. Group Members Paul Mamauag Mohamed Diab Kai Cha Ramazan Uku. Sheridan Institute of Technology and Advanced Learning Faculty of Applied Science and Technology School of Mechanical and Electrical Engineering Technology ENGI10679 Engineering Material and Testing Lab Report.

On the other hand while lower temperatures do yield a difference in hardness there is overall only a minimal or no change. Effect of heat treatment on mechanical properties and microstructure of O1 Tool Steel. We will be using 4340 and eutectoid steel.

Outer bell is the heat lab report of tolansky interference light microscopy usually controlled to go back to change from one example allowing only be lowered. However the carbon has a low solubility in bcc iron and precipitates as iron carbide when steel is cooled from 1600ºF 870C. This is achieved through a process referred to as heat treatment.

Use tongs to insert or remove the specimens from the furnace. Heat in carbon rich environment to 1600F. Heat in oven to 1600F ii.

Heat treatment is a method used to aIter the physical chemical and mechanical properties oI a material to various temperatures. Heat treatment is widely used in engineering industry because it can aIter the size shape and composition oI a material. Heat Treatment of Steels Common steels which are really solid solutions of carbon in iron are body-centered-cubic.

Performed by Group 001A With TA Patrick. Solution Heat Treatment is a treatment in which an aluminum alloy is heated to a suitable temperature and held at this temperature for a sufficient length of time to allow the desired constituent to enter into the solid solution followed by rapid cooling to hold the constituent in the solution. The heat-treating process is consists of three crucial steps.

There is the heat treatment lab report politeknik metal surfaces on the experiment succeeded in honey but also the microconstituent of volatiles of applied load. To observe the heat treatment process for a 4340 and a eutectoid steel sample. Make a period of these temperatures were cooled slowly that it is suggested that a large decrease in order will be considered as on.

Lab Report the method by which metals are heated and cooled in a series of specific operations that never allow the metal to reach the molten state. The processes of precipitation can be altered by adjusting the cooling rate. Section ME215-004 Instructor Professor Samardzic.

What is solution heat treatment. Aluminum alloys that can be heat treated to form these precipitates are considered heat treatable alloys. Download a pdf copy of the MSE department lab report format to be used with the Heat Treatment Lab.

Objective To understand the effects of heat treatment on the microstructure and property of a material 3. Each team had three different types of metal 1020 1045 and 4140 Steel that would be heated to 1550 F. Testing Of Concrete Lab Report.

Austenite increased as temperature of stainless steel is a heat treatment of steel lab report of steel to increase ductility transmission electron microscope. Date Performed 3520 Date Submitted 330 Course.

Pdf Effect Of Heat Treatment On Mechanical Properties And Microstructure Of Nst 37 2 Steel

Objectives Of Heat Treatments Pdf Heat Treating Annealing Metallurgy

Heat Treatment Lab Pdf University Of Guelph School Of Engineering Engg 2120 Heat Treatment Of Steels Ryan Clemmer I7 Ameer Alwash Ahmed Waheed Anmol Course Hero

Solved Problem Statement Normalizing Is A Heat Treatment Chegg Com

Heat Treatment Lab Report Madalynngwf

Connect With Us Through The Asian Connect App To Book Appointments Check Lab Reports And Do Much More In A Flash Medical Science Health Care Medical Treatment

Heat Treatment Report Instructions Fall06

Theory Of Heat Treatment Pdf Heat Treating Annealing Metallurgy

Lab Report Heat Treatment Of Steel

Solved Mce 2303 Lab Report Heat Treatment And Hardness Test Chegg Com

Pdf Heat Treatment Of Steel Measurement Of Hardness And Tensile Strength A Case Study At The Laboratory

Doc Heat Treatment Lab Arsalan Khan Academia Edu

Lab Report Jominy Test Introduction The Purpose Of This Lab Called Jominy Test Was To Study Hardness As A Function Of Quench Rate Also We Course Hero

Materials Science Laboratory Heat Treatment Of Steels Chegg Com

Experiment 2 M E T U Department Of Metallurgical Materials Engineering Mete 206 Property Control By Heat Treatment Experiment 2 Student Name Course Hero

Heat Treatment Laboratory 02 Heat Treatment Lab Pdf Staple Here Today S Date Full Name Current Quarter Year Bronco Id Course Hero

Lab Report Heat Treatment Of Steel